У нас есть страсть к нетрадиционным решениям, которые приносят ваше видение в жизнь.

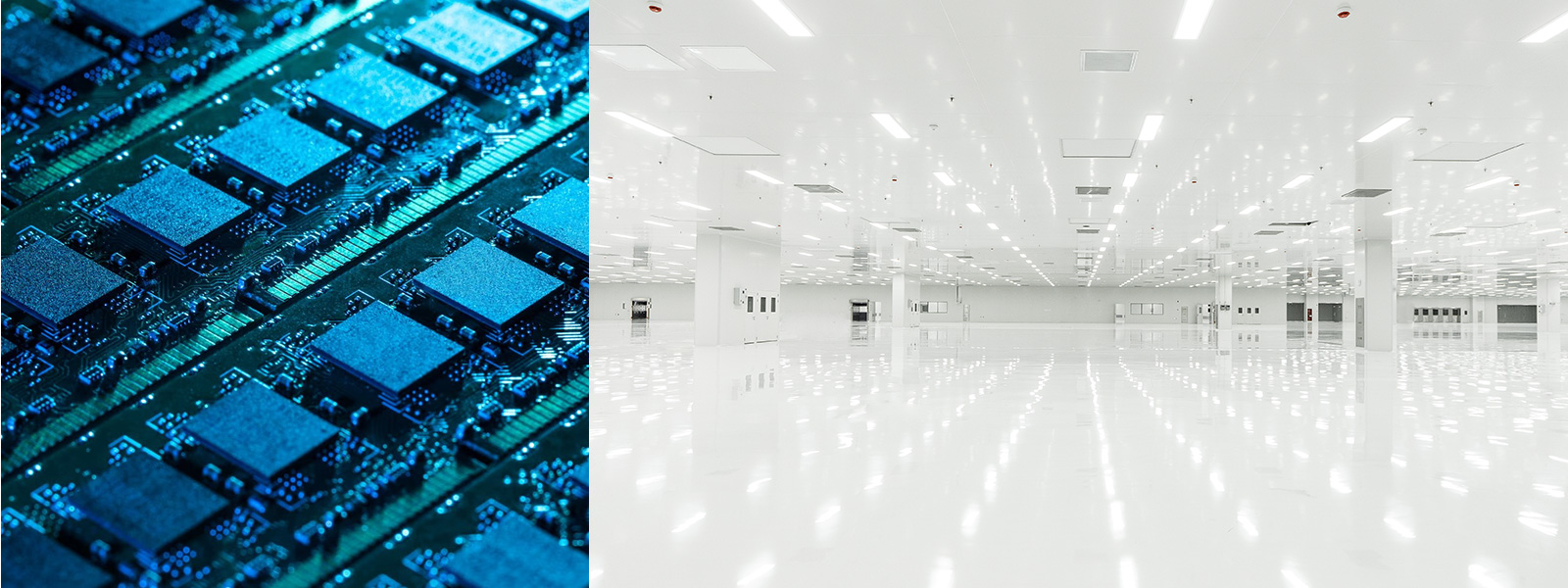

Electronic & Semiconductor

Semiconductor cleanrooms represent the most stringent controlled environments globally. As photolithography linewidths drop below 0.1 micron, these facilities typically achieve class 10 or class 100 classifications, equivalent to ISO-4 or ISO-5 standards. Moreover, they enforce extremely precise temperature and humidity controls. The scale of semiconductor cleanrooms can range widely, from compact spaces of several hundred square feet to expansive areas exceeding half a million square feet.

Semiconductor cleanrooms rely on ULPA filters instead of standard HEPA filters to prevent even the smallest submicron particles from compromising the semiconductor clean room environment. HEPA filters capture 99.97% of particles at 0.3 microns, whereas ULPA filters deliver 99.999% efficiency at 0.12 microns, creating the ultra-pure conditions essential for modern chip fabrication.

The iconic amber lighting found in semiconductor cleanroom photolithography zones protects sensitive photoresist layers used to etch patterns onto semiconductor wafers. Ordinary white light would prematurely expose this material, but the amber spectrum poses no risk. For ISO-5 (class 100) and stricter cleanroom semiconductor spaces, 100% ULPA ceiling coverage ensures seamless vertical airflow everywhere. Custom teardrop fixtures installed between ULPA filters on the t-grid provide necessary illumination while preserving perfect laminar flow.

The most popular flooring solutions in a semiconductor clean room are static-dissipative heat-welded vinyl sheets or raised access floor systems. Static-dissipative vinyl shields delicate semiconductor components from harmful electrostatic discharge during handling and assembly. Raised flooring channels ULPA-filtered air directly downward from ceiling units to subfloor returns, achieving optimal unidirectional flow. By comparison, traditional low-wall returns force air sideways across the room, which can disturb particle settlement and reduce overall cleanliness.

Ultra-fine feature sizes make semiconductor cleanroom processes extraordinarily sensitive to even minor temperature or humidity shifts. Typical tolerances demand ±1 degree Fahrenheit and relative humidity control within ±5–10%. This level of precision requires room-specific air handlers with integrated heating and cooling coils. Virtually all high-end semiconductor cleanrooms include dedicated chillers and boilers to guarantee uninterrupted HVAC performance.

Operators in semiconductor clean room facilities wear complete bunny suits complemented by booties, hoods, face masks, and gloves to block human-generated particles. After full gowning, personnel routinely enter an air shower that blasts HEPA-filtered air across the suit exterior, removing any lingering contaminants before they can enter the critical cleanroom semiconductor zone.

Wiskind Cleanroom специализируется на разработке, производстве, продаже, консалтинговых и сервисных услугах.